Preventing wall panels from cracking is essential for maintaining both structural integrity and aesthetic appeal. You need to understand the common causes of cracking, from material selection to environmental factors. It’s not just about choosing the right panels; proper installation and ongoing maintenance play significant roles, too. Are you aware of how humidity levels and temperature fluctuations can impact your panels? Let’s explore these elements further to guarantee your walls remain in ideal condition.

Understanding the Common Causes of Wall Cracking

Although wall cracking can occur for various reasons, understanding the underlying causes is essential to prevention. You should be aware of the different crack types, as they often indicate specific issues. For instance, hairline cracks may arise from natural settling, while wider fissures could signal more severe problems, threatening your wall’s structural integrity. Moisture intrusion, temperature fluctuations, and inadequate support can exacerbate these cracks, leading to costly repairs. By identifying these factors early, you can take proactive measures to mitigate damage and maintain your wall panels’ durability. Knowledge is your best defense against the oppressive forces that cause wall cracking.

Choosing the Right Materials for Wall Panels

When choosing materials for wall panels, you need to take into account durability to guarantee long-lasting performance. Additionally, moisture resistance features are vital to prevent damage from humidity and water infiltration. Balancing weight and thickness is also important, as it impacts structural integrity and ease of installation.

Material Durability Considerations

Choosing the right materials for wall panels is essential for ensuring long-term durability and performance. You’ll want to prioritize material flexibility, as it allows the panels to adapt to structural movements without cracking. Look for options that offer high impact resistance, which minimizes damage from accidental collisions or heavy loads. Materials like fiberglass-reinforced composites or engineered wood provide excellent durability while maintaining lightweight properties. Evaluating the combination of these characteristics will help you select wall panels that not only withstand stress but also enhance the freedom of design and functionality within your space. Make informed choices to prevent future issues.

Moisture Resistance Features

In addition to material durability, moisture resistance is an essential aspect of wall panel selection. You’ll want to choose materials with effective moisture barriers that prevent water infiltration, which can lead to cracking and structural damage. Look for wall panels that incorporate waterproof coatings, enhancing their ability to resist moisture and maintain integrity over time. These features not only protect the panels but also contribute to a healthier indoor environment by minimizing mold and mildew growth. By prioritizing moisture resistance, you’re ensuring the longevity of your wall panels while enjoying the freedom of an aesthetically pleasing and functional space.

Weight and Thickness Balance

Balancing weight and thickness is essential for selecting wall panels that meet both structural integrity and aesthetic requirements. You need to guarantee ideal load distribution while maintaining panel flexibility to prevent cracks. Here’s a quick comparison of materials to guide your choice:

| Material | Weight (lbs/sq ft) | Thickness (inches) |

|---|---|---|

| Plywood | 1.5 | 0.5 |

| MDF | 2.0 | 0.75 |

| Steel | 3.0 | 0.5 |

| Composite | 1.8 | 0.625 |

Choose wisely to enhance both durability and design freedom.

Proper Installation Techniques to Prevent Cracking

To prevent cracking in wall panels, you must select quality materials that withstand environmental stresses. Additionally, adhering to manufacturer guidelines during installation is essential for ensuring structural integrity. Both factors greatly contribute to the longevity and performance of the wall panels.

Choose Quality Materials

Choosing quality materials is essential for preventing wall panels from cracking, especially when considering the stresses they may face over time. Different material types, such as fiber cement or high-density gypsum, offer varying levels of durability and flexibility. Investing in superior materials often reduces long-term installation costs by minimizing repairs and replacements. While cheaper options might seem appealing upfront, they can lead to significant expenses down the line due to cracking. By selecting robust materials, you enhance the integrity of your wall panels, ensuring they withstand environmental factors and maintain their appearance for years to come, ultimately supporting your desire for freedom in design.

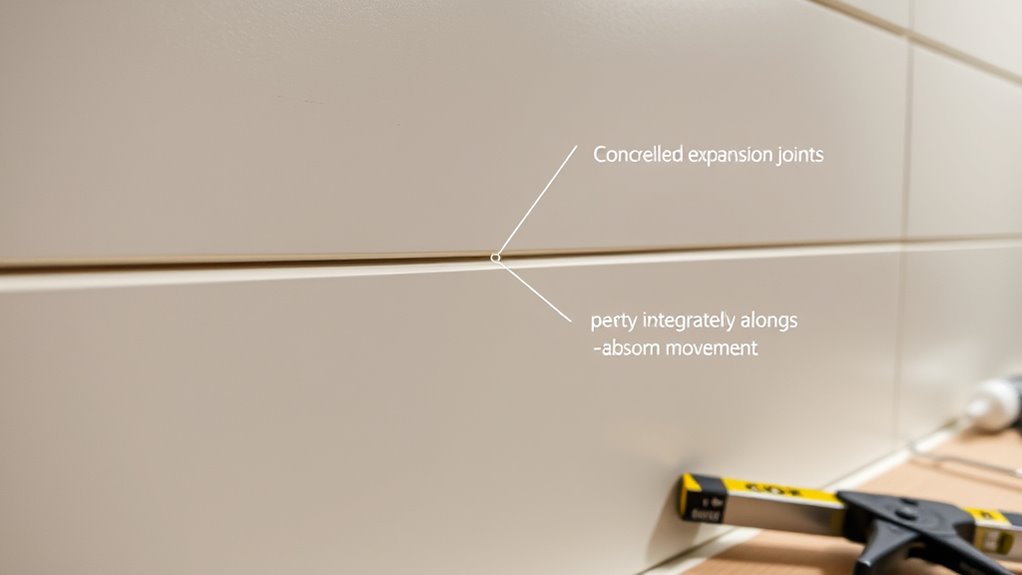

Follow Manufacturer Guidelines

Although it may seem straightforward, following manufacturer guidelines during the installation of wall panels is vital for preventing cracking. Adhering to manufacturer specifications guarantees that you’re using the right materials and techniques suited for the specific product. Installation manuals provide essential information regarding spacing, fasteners, and environmental conditions, which can greatly impact the integrity of the panels. Neglecting these details can lead to misalignment or excessive stress on the materials, resulting in cracks. By respecting these guidelines, you empower yourself to achieve peak performance and longevity from your wall panels, ultimately enhancing both aesthetics and structural stability.

Maintaining Optimal Humidity and Temperature Levels

Maintaining ideal humidity and temperature levels is essential for preventing wall panels from cracking, as fluctuations can lead to material stress and structural damage. Implementing effective humidity control and temperature regulation can preserve your wall panels’ integrity. Consider these three actions:

- Use a Dehumidifier: Keep humidity levels between 30-50% to minimize moisture-related issues.

- Install Thermostats: Regulate indoor temperatures, ideally between 60-75°F, to prevent expansion and contraction of materials.

- Monitor Seasonal Changes: Adjust your climate control systems as seasons shift to maintain consistent conditions.

Regular Inspections and Early Detection of Cracks

Regular inspections play an essential role in preserving the integrity of wall panels. By adopting a consistent inspection frequency, you can enhance crack detection and identify potential issues before they escalate. Aim for quarterly assessments, examining joints, seams, and surfaces for any signs of wear or fissures. Utilize tools like moisture meters or acoustic sensors to aid in identifying hidden cracks. Documenting your findings allows for trend analysis, ensuring proactive measures can be implemented. Remember, early detection is key; it not only saves time and resources but also maintains the aesthetic and structural integrity of your wall panels.

Repairing Minor Cracks Before They Become Major Issues

Addressing minor cracks promptly can prevent them from evolving into significant structural problems. For effective repair, follow these steps:

Timely repair of minor cracks can avert major structural issues down the line.

- Surface Preparation: Clean the crack with a wire brush to remove debris and loose material, ensuring a solid bond.

- Crack Sealing: Apply a high-quality sealant, filling the crack completely to prevent water infiltration and further expansion.

- Finishing Touches: Smooth the surface with a putty knife for an even finish, blending it seamlessly with the surrounding area.

Frequently Asked Questions

Can Wall Panels Be Painted Without Risking Cracks?

You’d think painting wall panels guarantees cracks, right? But with proper paint types and application techniques, you can achieve a flawless finish. Just make certain your surface is prepped, and your choices are compatible for best results.

How Do Different Climates Affect Wall Panel Integrity?

Different climates considerably impact wall panel integrity. High humidity can lead to expansion, while arid conditions might cause contraction. Understanding these climate impacts and humidity effects is essential to maintain your wall panels’ longevity and performance.

Are There Specific Wall Panel Designs That Resist Cracking?

Yes, certain wall panel designs utilize flexible design materials and enhanced structural support, which help resist cracking. Opting for modular panels or those with reinforced joints can greatly improve durability across varying environmental conditions.

What Tools Are Best for Inspecting Wall Panels?

For effective inspections, use tools like thermal imaging cameras, moisture meters, and acoustic devices. These inspection techniques provide precise insights, helping you assess panel integrity and guarantee long-lasting performance without compromising your freedom to create.

How Often Should I Inspect My Wall Panels?

You should inspect your wall panels at least twice a year for ideal wall panel maintenance. This inspection frequency helps identify issues early, ensuring the longevity and structural integrity of your panels while maintaining your freedom of space.